From jewelry to electronics, laser machines have become increasingly popular for a wide variety of applications. From engraving intricate designs onto precious metals to cutting through complex materials, laser machines offer precise and efficient solutions that are suitable for many different industries.

This article will explore the diverse range of uses for these powerful tools, from industrial production lines to small-scale hobbyists. Well, discuss how the technology works and why it has become so widely used in today\’s world.

Finally, will look at some of the potential risks associated with using them and what safety precautions should be taken when operating them.

Lasers Used for Electronics Manufacturing

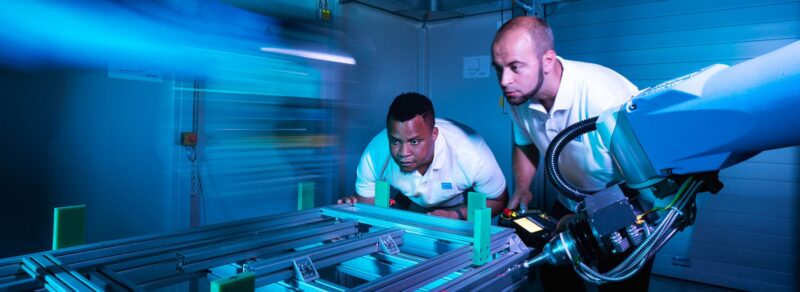

Lasers have revolutionized electronics manufacturing, making the process faster and more precise than ever before. By focusing a high-powered beam of light onto a specific area, lasers can cut through materials with efficiency and accuracy, allowing for intricate designs to be created quickly and without wasting resources.

Lasers are used in many different stages of electronics manufacturing, from etching circuits onto printed circuit boards (PCB) to cutting electronic components for assembly into devices such as smartphones or computers. Not only does laser technology speed up production times; but it also enables manufacturers to create highly detailed designs that would otherwise be impossible with traditional methods – perfect for advanced technologies like automation systems or sophisticated medical devices.

Laser machines offer an extremely cost-effective way of producing complex electronics with minimal wastage, meaning manufacturers can produce products at a fraction of the time and cost compared to manual processing methods. With its ability to work on any material including rubber, plastic metal, or glass – laser technology is now being utilized in virtually every corner of the electronics industry!

The Benefits of Using Laser Machines

The use of laser machines has a wide range of applications, from jewelry to electronics. From cutting and engraving metals to creating intricate designs on glassware, these powerful tools can do it all.

While the versatility of laser machines is undeniable, many practical benefits come with their use. One primary benefit is the precision of results when using a laser machine.

They offer incredibly precise and accurate cuts and etchings that would be difficult or impossible for humans to achieve by hand. This makes them ideal for projects where exact measurements must be taken into account such as in engineering and manufacturing operations.

Additionally, they require minimal setup time and provide consistent results each time they are used – making them an invaluable asset in production lines requiring speediness without compromising quality standards. Another advantage to using laser machines is their cost-effectiveness compared to traditional methods of cutting or engraving materials like wood or metal which often require specialized equipment or manual labor with varying levels of precision depending on skill level.

Laser technology allows users to create detailed pieces quickly without having to invest heavily in machinery or manpower; further contributing towards reducing overhead expenses for businesses while still producing premium products minus any wastage due to inaccurate cuts or etching processes traditionally associated with manual operations. Finally, advanced laser machines also offer greater efficiency than other alternatives as they don’t require frequent maintenance like mechanical cutters do since wear parts aren’t necessary when relying solely on light energy directed via optics lenses onto target material surfaces instead employing more robust electronic components that need less adjusting over time – saving both money and resources in the long run!

Challenges of Utilizing Laser Machines

Using laser machines to create products comes with its own set of challenges. Firstly, the skill needed to operate and program the machine is complex and requires knowledge that can only be gained through extensive training.

Secondly, there are safety considerations when using a laser cutter or engraver as they generate heat which can cause harm if not handled correctly. Thirdly, precision and accuracy are extremely important for these machines to produce quality results; any discrepancies could result in costly mistakes or delays in production times.

Lastly, high-power lasers require reliable cooling systems and frequent maintenance to ensure optimal performance at all times.

Conclusion

The Laser Machines have found a wide variety of applications, ranging from jewelry to electronics. This illustrates the incredible diversity that laser machines can bring in terms of their uses.

The Laser Machines have found a wide variety of applications, ranging from jewelry to electronics. This illustrates the incredible diversity that laser machines can bring in terms of their uses.

By providing powerful cutting capabilities with great accuracy, these machines offer an effective way to create products for many different industries. Laser Machines are now a mainstay in manufacturing processes and will continue to be an important part of diverse applications for years to come.