Investing in laser cleaning machines for metal has become increasingly popular due to the many economic benefits it can bring. These machines are not only efficient, but they also help reduce costs and increase productivity across a range of industries.

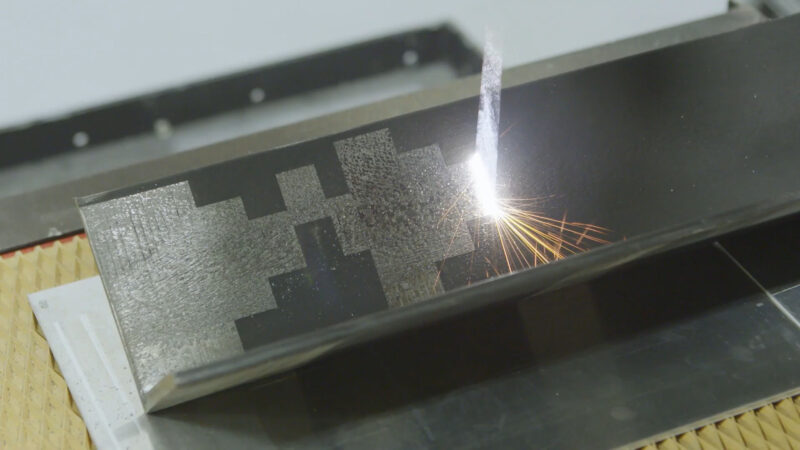

Laser cleaning is an effective way to remove rust, paint, grease, dirt, and other contaminants from metal surfaces without causing any damage to the material underneath. This technology offers numerous advantages over traditional methods such as sandblasting or chemical treatments which often damage delicate materials or require extensive labor hours.

With laser cleaning machines for metals becoming more widely available and cost-effective, businesses around the world are now beginning to realize the potential savings that this technology can offer them.

Increased Production Efficiency

Investing in laser cleaning machines for metal can increase production efficiency and have a positive economic impact. Companies that choose to invest in these machines will be able to speed up their manufacturing processes, as the powerful lasers quickly and precisely remove dirt, rust, paint, and other contaminants from metal surfaces.

This not only improves the quality of products but also reduces costs by eliminating any post-production clean-up time. Furthermore, the decrease in downtime due to fewer manual labor procedures translates into increased efficiency and higher output volumes which directly boosts profits over time.

Laser cleaning technology also enables more accurate results with less waste than traditional methods while reducing health risks associated with chemical solvents or abrasive materials used in other industrial operations. In short, investing in laser cleaning technologies is a wise decision that can bring about long-term economic benefits for businesses across all industries.

Improved Quality of Cleaned Parts

Investing in laser cleaning machines for metal can provide a tremendous boost to the quality of your finished parts. These innovative tools can remove dirt, rust, and other contaminants from metal surfaces with remarkable precision.

This leaves behind clean components that can be used in a variety of applications. The result is improved performance and longevity, making them an excellent choice for businesses looking to maximize their overall return on investment. Additionally, these machines offer significant savings in labor costs as they don’t require manual scrubbing or abrasive methods, which can take much longer and cost more money in the long run.

Laser cleaning also eliminates the need for harsh chemicals that can damage delicate parts or corrode metals over time – saving you both time and money! With all these benefits combined, it’s easy to see why investing in laser cleaning machines for metal is one of the most sensible investments any business can make when it comes to improving part quality.

Enhanced Safety for Workers and the Environment

Investing in laser cleaning machines for metal can bring immense economic benefits, but also enhanced safety for workers and the environment. Laser cleaning technology eliminates hazardous particulates that are generated when using traditional methods such as sandblasting or chemical stripping.

This means that businesses no longer need to worry about hurting their employees’ health, nor will they have to deal with any environmental pollutants caused by these processes. Furthermore, since laser cleaning is so precise it can be used in areas where sandblasting and other abrasive techniques would not be suitable due to their potential for damage.

This allows organizations to create cleaner workspaces without compromising the safety of their staff or putting the environment at risk. In conclusion, investing in laser cleaning technology has many benefits – from economic gains to improved worker safety and protection of the natural environment – making it an invaluable investment for any business looking to increase efficiency while avoiding unnecessary risks.

Conclusion

Investing in laser cleaning machines for metal can provide numerous economic benefits, from reducing the cost of labor to increasing efficiency and productivity. Laser cleaning technology provides a safe, reliable, and economical way to clean off dirt, rust, or other contaminants that have built up on metal surfaces over time.

This method is more efficient than traditional methods such as sandblasting or manually scrubbing off dirt with abrasive tools. Furthermore, this technique uses minimal water which reduces costs associated with the disposal of contaminated wastewater.

In addition, it is easy to use and does not require any special training for operators making it an excellent choice when considering investments in industrial equipment. With all these advantages put together, investing in laser cleaning machines for metal can be highly beneficial economically.