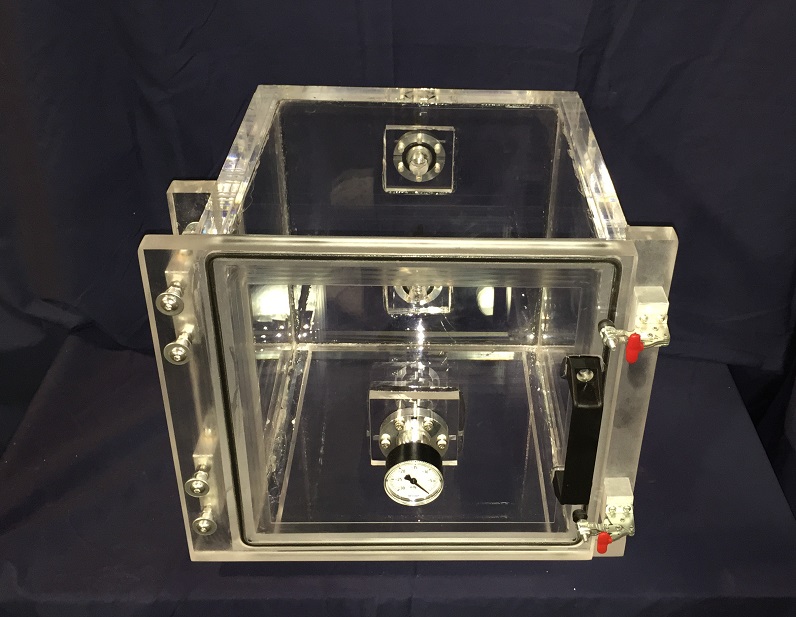

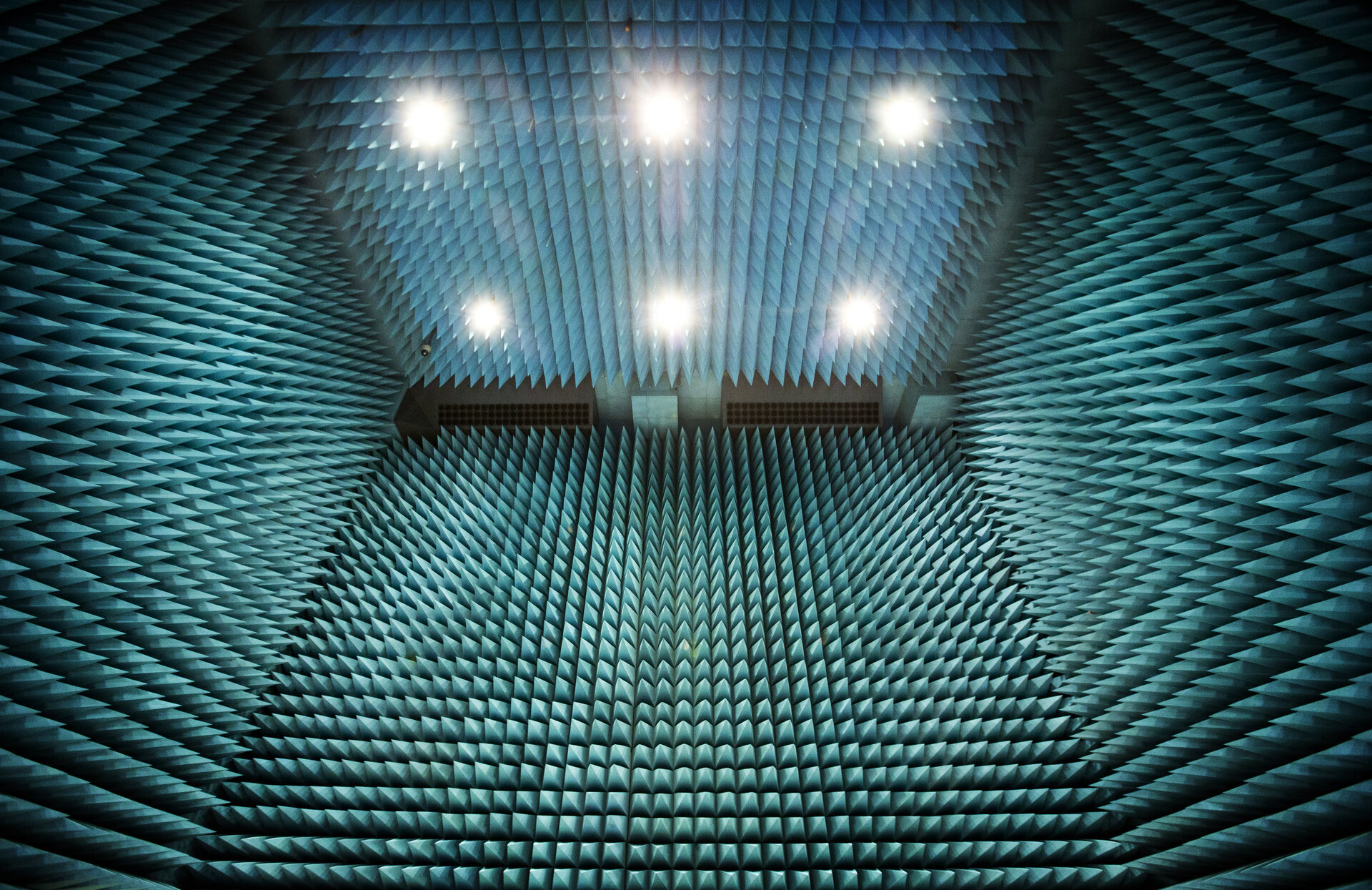

The importance of test chambers in ensuring product durability and reliability cannot be understated. Test chamber is used to simulate environmental conditions, allowing companies to accurately determine the effects of age, humidity, temperature, and other external factors on a wide variety of products.

By testing products in these controlled environments, manufacturers can identify potential weaknesses that could lead to product failure and take corrective action before it is too late.

Through rigorous testing in test chambers, companies can ensure that their products meet the highest standards for quality assurance and customer satisfaction.

Benefits of Utilizing Test Chambers

The benefits of utilizing test chambers are numerous. One of the main advantages is that it allows manufacturers to replicate a wide variety of environmental conditions to ensure product durability and reliability.

This eliminates the need for extensive field testing which can be both costly and time-consuming. Test chamber enables companies to identify potential design flaws before they become major problems, saving money on repair or replacement costs.

Additionally, test chambers reduce labor costs as fewer technicians are needed compared with traditional methods such as manual inspections or external laboratory tests.

Finally, the modern-day test chamber offers greater control over experiments than ever before while producing accurate results within shorter periods – making it perfect for tight deadlines or quick fixes when needed urgently!

The Role of Test Chambers in Ensuring Durability and Reliability

Test chambers play a critical role in ensuring the durability and reliability of products. By allowing manufacturers to simulate a variety of environmental conditions, test chambers provide an accurate assessment of how products will fare over time.

This allows companies to identify potential weaknesses before they become major problems in the field and can help prevent costly repairs or product failures down the line. Additionally, by testing multiple components at once, test chambers reduce costs associated with labor as fewer technicians are needed for each chamber compared to traditional methods like manual inspections or lab tests.

Test chambers are also more efficient since they require shorter periods for producing results than older models making them perfect for tight deadlines or quick fixes when needed urgently!

Ultimately, utilizing test chamber technology is essential in guaranteeing that products meet necessary standards and customer expectations across different environments while saving both time and money on development costs.

Common Applications for Testing with a Test Chamber

Testing with a Test Chamber is an important part of ensuring product durability and reliability. Common applications for testing products in the test chamber technology include environmental testing, such as temperature, humidity, and pressure testing; vibration testing to assess the resilience of components against fatigue from mechanical shocks or vibrations; salt-spray corrosion tests to check how a product’s material will react when exposed to salt spray; altitude tests that simulate high-altitude conditions; shock tests to determine how much physical force a product can withstand without damage; and rain simulations that examine water resistance.

In addition, test chambers are also used for various types of electrical performance tests including those related to dielectric strength and insulation resistance. By subjecting products to these different types of extreme environments, manufacturers can gain valuable insights into their durability and reliability before they go out into the real world.

Conclusion

Test chambers are an essential tool for ensuring product durability and reliability. By simulating harsh environmental conditions, test chambers can be used to evaluate the performance of a given product in extreme temperatures, humidity levels, and other conditions.

With the help of advanced battery testing equipment, manufacturers can accurately replicate these environments to identify any potential issues with their products before introducing them into the market.

Test chambers provide key insights into how products will perform under real-world conditions and enable companies to ensure that their goods meet consumer expectations in terms of quality assurance, safety, and longevity.